Version 1.5, 6 Apr 2013

Thread Milling Machine Operation

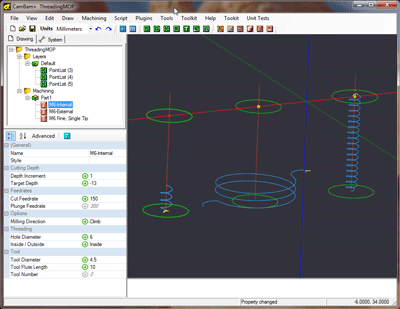

This plugin provides a machining operation to generate spiral toolpaths for use with thread milling.

Version 1.5

Download (latest stable release)

For CamBam version 0.9.8 (latest stable release)

Released 6 Apr 2013

download ThreadingMOP-1.5.zip (11 KB)

For CamBam version 1.0 (development release)

Released 27 Dec 2016

download ThreadingMOP-1.5-CamBamV1.0.zip (11 KB)

Version 1.2, 8 Jul 2012

Download (older)

download ThreadingMOP-1.2.zip (11 KB)

This version is for CamBam versions earlier than 0.9.8N only.

It will not work with later CamBam versions.

Installation

To install the plugin, unzip ThreadingMOP.dll into the CamBam plugins folder.

If the installation is successful, you should see a new entry: Thread Mill in the top CamBam Machining menu.

Usage

The thread milling operation behaves similarly to a spiral drilling operation and can be based on point lists, circles or other drawing objects

(for these, the center point of the selected object will be used).

The thread milling operation assumes a clearance hole has been previously drilled to the required minor thread diameter.

The machining operation will generate a spiral toolpath with the pitch of the thread set in the Depth Increment property.

TPI pitch values need to be converted to a distance measurement (for example 25 TPI set Depth Increment = 0.04 in).

The diameter of the thread is set in Hole Diameter.

For internal threads, this should be the major diameter of the required thread. For example, for an M8 thread, Hole Diameter would be 8.0.

For external threads, the minor or core diameter of the required thread should be used.

A helical tangent lead in and lead out move will always be inserted. The lead moves will ramp one half pitch in Z height.

The lead out height should be taken into account when setting the target depth. So if a 1mm pitch thread needs to be cut completely

through 10mm stock, the target depth should be set to -10.5mm.

For internal threads, the toolpath will start from the center point of the hole. For external threads the tangent radius

is currently fixed at half the tool diameter.

Bottom-up or top-down thread milling can be controlled using the Milling Direction property.

For example, if Spindle Direction is Clockwise, setting Milling Direction=Climb will result in a bottom-up cut

A multi-tip thread mill can be specified by entering in the Tool Flute Length property; for a single tip cutter this

can be set to zero. For multi-tip cutters (or when bottom-up machining), the tool will be lowered into the center of the hole using the plunge feedrate, down

to the staring point of the tangent lead in. A minimum of 1 spiral loop will be used and multiple loops will be inserted if the

flute length is less than the target depth. To intenionally mill more than a single loop a smaller value than the true flute length

may be entered.

Properties

Note, for clarity, some common properties are not shown here.

|

Clearance Plane

|

The clearance plane (offset from the work plane).

The clearance plane should be clear of the stock and any holding devices to allow free movement to any location.

There will be a move to the clearance plane between each thread cut.

|

|

Cut Feedrate

|

The feed rate to use when thread cutting.

|

|

Depth Increment

|

The depth increment controls the pitch of the thread being milled.

This is the depth of cut for each loop of the spiral.

|

|

Hole Diameter

|

For internal threads, this should be the major diameter of the required thread. For example, for an M8 thread, Hole Diameter would be 8.0.

For external threads, the minor or core diameter of the required thread should be used.

|

|

Inside / Outside

|

Controls whether to cut an Inside / Internal or Outside / External thread.

|

|

Milling Direction

|

Controls the direction the cutter moves around the toolpath.

Conventional | Climb | Mixed

This property, together with the Spindle Direction property will also control whether the thread is milled bottom-to-top or top-to-bottom.

|

|

Plunge Feedrate

|

The feed rate to use when plunging. This is used when the thread mill is lowered into the clearance hole.

|

|

Roughing Clearance

|

This is the amount of stock to leave after the final cut.

Remaining stock is typically removed later in a finishing pass.

Negative values can be used to oversize cuts.

|

|

Spindle Direction

|

The direction of rotation of the spindle.

CW | CCW | Off

This property, together with the Milling Direction property will also control whether the thread is milled bottom to top or top to bottom.

|

|

Stock Surface

|

This is the Z offset of the stock surface.

For multi-tip cuters or bottom up machining, the tool may be lowered into the clearance hole, below the stock surface, before cutting starts.

|

|

Target Depth

|

The Z coordinate of the final machining depth.

Note: The last half pitch of the thread will be a tangent lead out move, so target depth should be set an extra half pitch deeper

when a through thread is being cut.

|

|

Thread Handedness

|

Right Hand | Left Hand

Right hand threads are most common.

|

|

Tool Diameter

|

This is the diameter of the current tool in drawing units.

If the tool diameter is 0, the diameter from the tool information stored in the tool library

for the given tool number will be used.

Note! Some thread mills may have a different diameter to their description. It is a good idea to measure the cutter

and use the actual measured diameter here.

|

|

Tool Flute Length

|

This is the length of the cutting part of the thread milling cutter in drawing units.

For single tip thread mills, use 0 for the thread mill length.

For multi tip cutters, the flute length can be set to the number of teeth X thread pitch.

If this value is set to Auto, the flute length will be read from the tool library for the given tool number.

|

|

Tool Number

|

The ToolNumber is used to identify the current tool.

If ToolNumber changes between successive machine ops a toolchange instruction is created in gcode.

ToolNumber=0 is a special case which will not issue a toolchange.

The tool number is also used to look up tool information in the current tool library. The tool library is specified

in the containing Part, or if this is not present in the Machining folder level. If no tool library is defined the

Default-(units) tool library is assumed.

|

|

Tool Profile

|

The shape of the cutter (not used).

CamBam does not currently provide a thread mill tool profile.

|

Revision History

- Modified to work with CamBam 0.9.8N rc-9.

- Modified to work with CamBam 0.9.8N.

- Now uses Start Point for optimisation.

- Fixed bug where 'Hole diameter must be > tool diameter for spiral drill' error incorrectly reported for external threads.

- Fixed bug where roughing clearance and milling direction were incorrectly applied for external threads.