Documentation for the latest CamBam release is available here...

Lathe Machining Operation

Lathe Machining Operation

NOTE! The lathe code is new to version 0.9.8 and is still undergoing testing and development.

Treat any lathe gcode with caution and run simulations or air cuts before machining.

The Lathe machining operation has been provided as a plugin. In this way the plugin can be developed and updated independently

of the main CamBam application. It is also a demonstration of the ability to extend CamBam's machining capability using

user written plugins.

The file lathe-test.cb in the CamBam samples folder demonstrates the new lathe operation.

In this initial lathe release there are a number of limitations:

- Only profiling operations are currently supported. No facing, boring or threading support yet.

- Apart from the tool radius, there is no mechanism to define a lathe tool shape. The part should be drawn to allow for the cutter size

and shape.

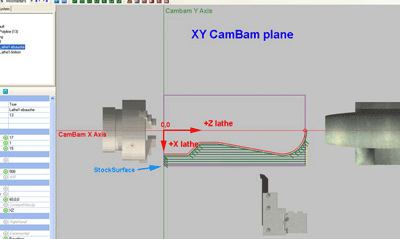

Drawing

A lathe profile can be generated from a 2D line representing the shape to machine.

The shape should be drawn so that:

The lathe +X axis is drawn in the -Y direction and

The lathe +Z axis is drawn in the +X direction.

This is so that the drawing will appear in the same orientation as when standing in front of a conventional lathe.

The toolpaths will be converted to standard lathe X and Z coordinates when the gcode is produced.

Only draw the profile line to be cut. Do not draw closed polylines, mirrored lines on the opposite side

of the turning axis or lines along the turning axis as the lathe operation will try to cut these as well which

will cause problems.

The profile line can be drawn anywhere in the drawing. If this line is away from the origin, the Machining Origin

should be set so that it lies on the axis of rotation and at the Z=0 (lathe coordinate).

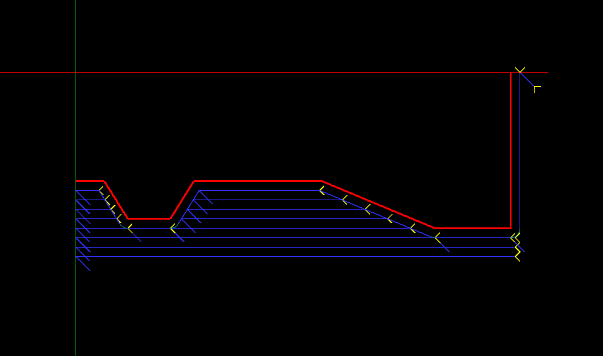

An example showing a profile where the machining 0,0 point is the same as the drawing origin.

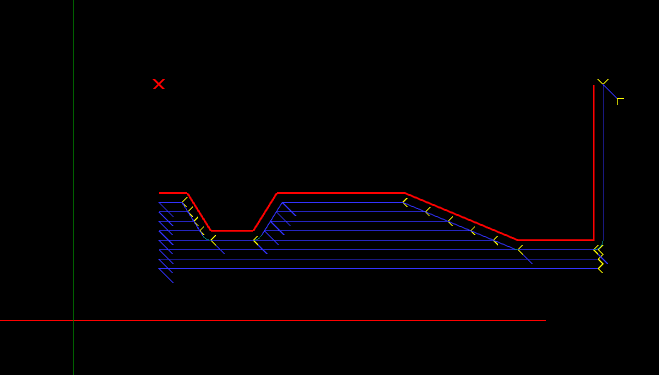

The same pattern drawn away from the origin, where the machining origin (red X) has been moved to indicate the lathes X=0, Z=0 point.

You can set the machine zero by setting MachiningOrigin property of the machining or part objects.

Click the  button to the right of the MachiningOrigin property to select the machine zero

point on the drawing.

button to the right of the MachiningOrigin property to select the machine zero

point on the drawing.

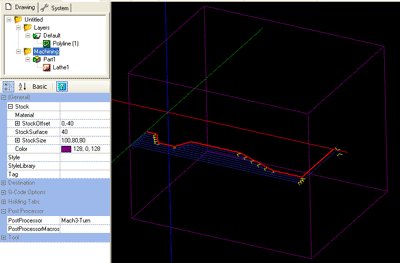

Stock Object

The lathe operation can use information from the stock object if one is defined, to determine properties such as stock

surface and the machining envelope.

CamBam's stock definition does not currently support cylindrical stock so the

stock will be shown as a rectangular block.

The following image shows a stock objects of 9-mm diameter and 100mm long (purple cube).

If the Stock Surface property is set to Auto, the stock object size is used to define it.

- The X size will be the length of the stock (along the lathe's Z axis).

- The Z and Y size should both be set to the stock diameter.

- StockSurface should be set to the stock radius.

- The Stock offset Y value should be set to negative the stock radius.

Using the Lathe Operation

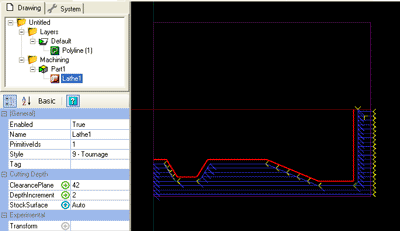

Select a suitable profile line, then insert a lathe operation by selecting the top Machining menu, then select  Lathe.

Lathe.

Note - The lathe plugin does not currently add an icon to the toolbar or drawing context menu.

Make sure the following are set:

- Workplane is set to XZ.

- Stock surface equals the radius of the stock.

- Clearance plane is greater than the radius of the stock.

- The machining origin is set along the axis of rotation.

- The tool diameter is set to twice the tool nose radius.

- The tool profile is set to Lathe.

- The correct RoughingFinishing option is set.

- If Roughing, a small RoughingClearance value is set.

- DepthIncrement and feedrates are appropriate for the material.

- Define the stock object if needed.

- A suitable post processor such as Mach3-Turn or EMC-Turn are selected in the Machining properties.

Properties

|

Clearance Plane

|

The safe X lathe coordinate to avoid any stock. The clearance plane value should always be expressed as a radius.

|

|

Custom MOP Footer

|

A multi-line gcode script that will be inserted into the gcode post after the current machining operation.

|

|

Custom MOP Header

|

A multi-line gcode script that will be inserted into the gcode post before the current machining operation.

|

|

Cut Feedrate

|

The feed rate to use when cutting.

|

|

Depth Increment

|

When roughing, this is the radial X distance between each parallel cut.

|

|

Enabled

|

True: The toolpaths associated with this machining operation are displayed and included in the gcode output

False: The operation will be ignored and no gcode or tool paths will be produced for this operation.

|

|

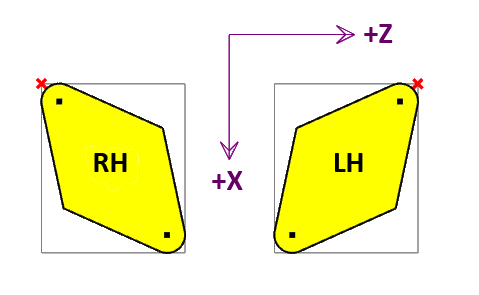

Lathe Cut Direction

|

- Right Hand - Cuts will move from right (+Z) to left (-Z).

- Left Hand - Cuts will move from left (-Z) to right (+Z).

|

Lathe Lead In Length

New [0.9.8N]

|

Controls the length of the 45 degree lead in moves. A zero value will disable these moves.

|

Lathe Lead Out Length

New [0.9.8N]

|

Controls the length of the 45 degree back away moves. A zero value will disable these moves.

|

|

Max Crossover Distance

|

Maximum distance as a fraction (0-1) of the tool diameter to cut in horizontal transitions.

If the distance to the next toolpath exceeds MaxCrossoverDistance, a retract, rapid and plunge to the next position, via the clearance plane, is inserted.

|

|

Name

|

Each machine operation can be given a meaningful name or description.

This is output in the gcode as a comment and is useful for keeping track of the function of each machining operation.

|

|

Optimisation Mode

|

An option that controls how the toolpaths are ordered in gcode output.

New (0.9.8) - A new, improved optimiser currently in testing.

Legacy (0.9.7) - Toolpaths are ordered using same logic as version 0.9.7.

None - Toolpaths are not optimised and are written in the order they were generated.

|

|

Plunge Feedrate

|

The feed rate to use when plunging.

|

|

Primitive IDs

|

List of drawing objects from which this machine operation is defined.

|

|

Roughing / Finishing

|

The Roughing / Finishing property is used to select the machining method. If Roughing is selected, a number of straight

passes are used at each depth increment, down to the source shape + roughing clearance, followed by a single cut at the

roughing clearance distance that follows the shape. For Finishing, a single cut that follows the shape at the roughing clearance distance

is used.

|

|

Roughing Clearance

|

This is the amount of stock to leave after the final cut.

Remaining stock is typically removed later in a finishing pass.

Negative values can be used to oversize cuts.

|

|

Spindle Direction

|

The direction of rotation of the spindle.

CW | CCW | Off

|

|

Spindle Range

|

The pulley number or dial setting of the spindle for the target speed.

|

|

Spindle Speed

|

The speed in RPM of the spindle.

|

|

Start Point

|

Used to select a point, near to where the first toolpath should begin machining.

If a start point is defined, a small circle will be displayed at this point when the machining operation

is selected. The start point circle can be moved by clicking and dragging.

|

|

Stock Surface

|

This is the X offset of the stock surface at which to start machining.

Can be set explicitly or determined from the stock object. Stock surface should always be expressed as a radius.

|

Style

[New! 0.9.8]

|

Select a CAM Style for this machining operation.

All default parameters will be inherited from this style.

|

Tag

[New! 0.9.8]

|

A general purpose, multiline text field that can be used to store notes or parameters from plugins.

|

|

Tool Diameter

|

This is the diameter of the current tool in drawing units.

If the tool diameter is 0, the diameter from the tool information stored in the tool library

for the given tool number will be used.

|

|

Tool Number

|

The ToolNumber is used to identify the current tool.

If ToolNumber changes between successive machine ops a toolchange instruction is created in gcode.

ToolNumber=0 is a special case which will not issue a toolchange.

The tool number is also used to look up tool information in the current tool library. The tool library is specified

in the containing Part, or if this is not present in the Machining folder level. If no tool library is defined the

Default-(units) tool library is assumed.

|

|

Tool Profile

|

The shape of the cutter. The new Lathe tool profile should always be used.

If the tool profile is Unspecified, the profile from the tool information stored in the tool library

for the given tool number will be used.

|

|

Velocity Mode

|

Instructs the gcode interpreter whether or to use look ahead smoothing.

Constant Velocity - (G64) Smoother but less accurate.

Exact Stop - (G61) All control points are hit but movement may be slower and jerky.

Default - Uses the global VelocityMode value under machining options.

|

|

Work Plane

|

Should always be set to XZ for lathe code!

|

Post Processor

Three sample lathe specific post processor definitions have been provided : Mach3-Turn, Mach3-Turn-CV (Mach3 with CutViewer definitions) and EMC2-Turn.

These definitions may need to be customised to suit the configuration of those controllers.

This section describes some post processor properties that are relevant to customising the lathe gcode output.

|

Clearance Plane Axis

|

Used to specify which direction clearance moves are made. Usually Z for normal milling, but must be set to X for lathe turning operations.

|

|

Lathe X Mode

|

Controls whether the X lathe coordinates will be written to gcode as Radius, or a Diameter.

Depth Increment, Stock Surface and Clearance Plane parameters should always be specified as a radius, regardless

of the post processor Lathe X Mode setting.

|

|

Lathe Tool Radius Offset

|

If False, the toolpath at the center of the tool radius is output.

If True, an appropriate tool radius offset is applied. The toolpath will be offset by a negative tool radius in the lathe X axis.

The direction of the Z tool radius offset is determined by the cut direction.

For right hand cuts the toolpath Z will be offset by a negative tool radius. For left hand cuts, a positive tool radius Z offset is used.

In the diagram above, the red cross represents the toolpath reference point when Lathe Tool Radius Offset is set True. If False, the dot

at the tool radius center will be the reference point. The reference point is sometimes referred to as the 'Imaginary' or 'Virtual' tool point.

|

|

X Mode Diameter

|

Code to use to set X diameter mode (eg G7 for EMC2)

|

|

X Mode Radius

|

Code to use to set X radius mode (eg G8 for EMC2)

|

|

Invert Arcs

|

If set True, CW arcs will be output as CCW and vice versa. This may be useful for front face lathe operations.

|

|

Arc Output

|

Normal is the preferred setting and will use G2 and G3 codes to output arcs. Convert To Lines may be used

as a last resort if CamBam can not generate arc codes in a format compatible with the destination controller. Convert To Lines is

used with the Arc To Lines Tolerance property, where smaller tolerances will result in smoother curves but larger files.

|

Tool Definitions

A sample lathe tool library 'Lathe-mm' is provided. The tool library can be selected by changing the Tool Library

property in the Machining or Part options.

Tool libraries are currently designed to support milling cutters, rather than lathe. However there are a couple of parameters than

are useful to store in the tool library.

Tool Profile should always be set to the new Lathe option. Among other things, this instructs the post processor

to determine the tool radius from the tool diameter.

A new Comment property has been added. This is a text value that can be included by the post processor when

using the {$tool.comment} macro from with the ToolChange post processor section.

For example. CutViewer Turn recognises a gcode comment that defines the geometry of the lathe tool in the following format:

TOOL/STANDARD,BA,A,R,IC,ITP

Refer to the CutViewer Turn documentation for details of this description. Here is a summary of the parameters:

- BA - Back angle.

- A - Angle.

- R - Radius.

- IC - Inner circle.

- ITP - Imaginary Tool Point. 0=Tool Center, 3 for right hand offset, 4 left hand offset.

This example Comment property defines a right hand cutter with a 2mm radius, 40 degree back angle and 40 degree taper.

{$comment} TOOL/STANDARD,40,40,{$tool.radius},2,3 {$endcomment}