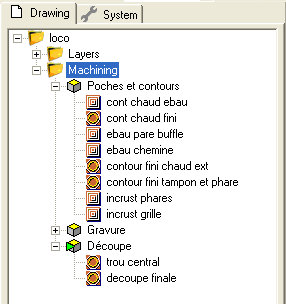

Part Machining Object

A Part is a way of grouping multiple, related machining operations into a single object. A single drawing file can contain many different part objects.

Parts can be enabled or disabled individually. As with layers and machining operations, pressing the space bar when the item is selected in the drawing tree, will toggle a part’s enabled state.

To generate the toolpaths for all the machining operations in a part, right click the part in the drawing tree, then select Generate toolpaths. Right click an individual machining operation to generate toolpaths for just that mop, and right click the Machining folder (or press CTRL+T) to generate toolpaths for all enabled operations in the drawing.

By default, generating gcode will write the output from all the enabled parts in the drawing. To create gcode for just one part, right click the part in the drawing tree, then select Produce gcode.

The file heart-shaped-box.cb, in the CamBam samples folder illustrates a good use of different parts. Here machining operations are separated into parts for front and back faces for the lid and base of a small wooden box.

Some of the Part properties such as

Properties

|

|

If |

|

|

A drawing point that will be used as the machining origin (X=0,Y=0) point when gcode is created. The ellipsis button An 'X' icon will be displayed on the drawing at the machining origin point. This cross can be dragged to a new location using the mouse. NOTE: MachiningOrigin replaces the GCodeOrigin and GCodeOriginOffset properties of earlier releases. |

|

|

A descriptive name for the part. This name will be used to generate a filename when creating gcode output from the part. |

|

|

This composite property provides a method of generating an array or nest of parts. When the toolpaths are generated, an outline should be displayed to indicate the location of each copy. The centre of

each outline contains a triangular icon. Clicking and dragging this icon will change the nesting pattern and will

also change the nesting method to

Multiple copies of the part's toolpaths will be written to the gcode output. This will increase the gcode file size, but does avoid some of the issues encountered when using subroutines. More detail is available on the Nesting documentation page. |

|

|

This is the location of the destination gcode file. Clicking the |

|

|

The stock object is used to define the dimensions of a block of material from which the part will be cut. The properties of the stock object can be used to automatically determine some machining properties.

Stock properties:

Stock is undefined if the X,Y and Z sizes are all zero. Stock can be defined at the part or machining level. Stock defined at the part level will override and machining level stock definitions and will be used for all operations within the part. The stock object dimensions can also be passed to simulators such as CutViewer when post processors with appropriate stock macros are included, such as the Mach3-CutViewer post processor. |

|

|

Select a default CAM Style for this part. All machining operations in the part will use this style unless set otherwise in the machining operation's Style property. |

|

|

This property is used to locate the style definitions used in the Part or machining operations. |

|

|

A general purpose, multi-line text field that can be used to store notes or parameter data. |

|

|

This is the diameter of the current tool in drawing units. If the tool diameter is 0, the diameter from the tool information stored in the tool library for the given tool number will be used. |

|

|

If left blank, the default tool library will be used (Default-{$Units}), otherwise the specified library will be used when looking up tool numbers. |

|

|

The ToolNumber is used to identify the current tool. If ToolNumber changes between successive machine ops a toolchange instruction is created in gcode. ToolNumber=0 is a special case which will not issue a toolchange. The tool number is also used to look up tool information in the current tool library. The tool library is specified in the containing Part, or if this is not present in the Machining folder level. If no tool library is defined the Default-(units) tool library is assumed. |

|

|

The shape of the cutter If the tool profile is Unspecified, the profile from the tool information stored in the tool library for the given tool number will be used.

|

to the right of this property can be used to select a point in the drawing.

to the right of this property can be used to select a point in the drawing.